Update, The original belts require:

- Replating or replacement of the hook portion

- 4 pcs of the plastic release tab.

- painting or plating of the attachment plates

- New webbing

- Stainless shackles for shoulder belt

- 3 New bolts for attachment.

- Shoulder belt bolts (I have these somewhere...)

- Stickers for buckle lifts.

- New 2" Webbing, around 16 ft. (84" per side.)

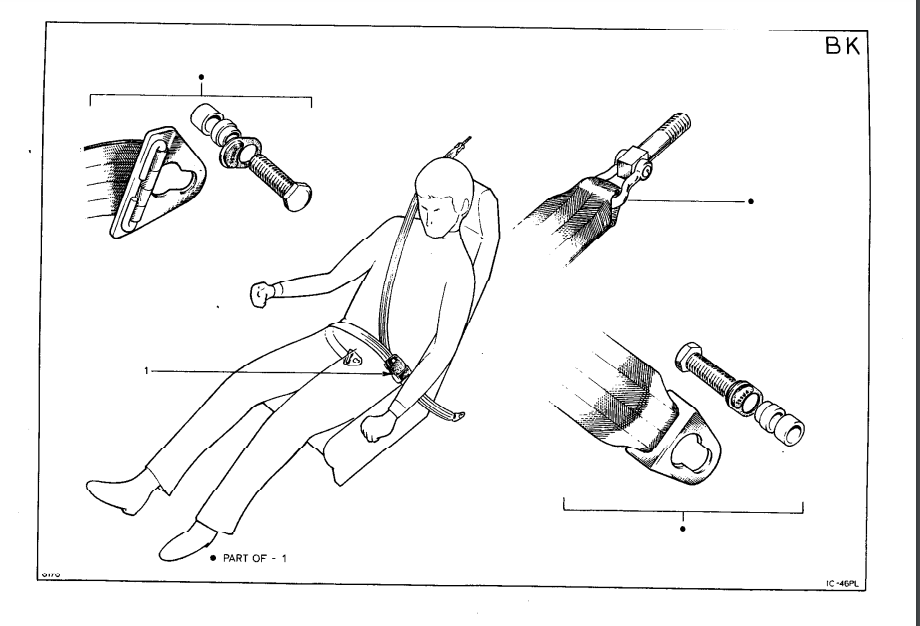

Can I restore these seatbelts?

I do wonder about how much safer a Europa really is with seatbelts. The guy in the pic below looks a bit tentative I think.

Emily car came with funky Kangol magnetic seatbelts. I have a vague memory of these from my youth, I can't recall in which car. I think they are cool and if I can restore them they'll add to the character of the car and the experience of driving. These are pretty straightforward compared to some of the shoulder belt options available in the late 60s.

I had decided these were beyond redemption but have been told they are and restorable. Will give it a shot.

The Attachment Points

There are of course three points of attachment. The outboard attachment points are not pictured in the parts manual, likely as they were integral with the body as provided to Lotus.

- inboard, threaded into a stud in the chassis.

- shoulder, into a rectangular plate pop riveted into in the flimsy fiberglass of the B pillar.

- Outboard, into an identical rectangular plate secured to a sheet steel plate bolted into the door sill.

This outboard plate is the most challenging to restore or reproduce as the plate is made of a particular quick-rusting steel alloy that is located in a strategic collection point for moisture and debris. Mine were in "average" condition, meaning that there weren't even DNA traces left. I do remember my gloved hand removing a handful of flaky rust from the sill 20 years ago.

Unfortunately the scant remains leave the restorer guessing.

Or not. The fine folks who frequent the Facebook Europa site came to the rescue with the information below, the first being a factory drawing of the original part(!) followed by a description of its fitment. (thanks Brian!)

You need to be careful with this or you can end up in a world of pain. Firstly the later cars and the TC used different length plates. To fit any of them you need to go back to how the cars were assembled. These plates were fastened to the floor section of the body mould using the 3/8 bolts into the captive nuts from what is the inside of the car. Then the upper part of the moulding was dropped into place and the lower section of the plate was sandwiched between the inner and outer body mouldings and fastened with pop rivets that run the whole length of the bottom joining seam. The commercially available plates will require you to split that seam again to get them in place, which is a pig of a job. You could cut them down but why pay a lot of money for something then have to modify it to fit. The alternative is to make your own plates that are narrower so they fit above the join in the body panels but make sure you have got any rusty parts of the originals out and splash some rust cure into the seam and hope the remains of the old plates haven't started to blow the seam open. You will have to measure the width required for your car as I have never found 2 cars that were the same. The 90 deg return edge on the plates were to give some rigidity but if you use some thicker stainless steel to make them this isn't essential unless you have a metal folding machine to hand. The notation on the attached pic is for a LHD car.

And finally some original parts

The online discussion quite rightly points out that the mounting plate spans the height of the door sill, thereby utilizing the horizontal skins of the sill and the floor to support it in event of a collision. My challenge will be to recreate this mounting in a way that improves on the factory approach.

The Belts

I have taken several photos so that I can reassemble the parts correctly if things work out. The latching portion of the buckles seemed to be in reasonable shape however the chrome-plated hook portion is badly corroded as - unsurprisingly - are the zinc-plated lower attachment points.

The push-tab clip on lower attachment stud bolts are in poor condition as well, and if the belts are to be replicated a simple bolt-on plate may be in order.

Comments

Post a Comment